-

Small automotive parts progressive die stamping parts

Our Small automotive parts progressive die stampin...

-

Deep drawing mold for front and rear wheels of two-wheeled electric vehicles

This Deep drawing mold for front and rear wheels o...

-

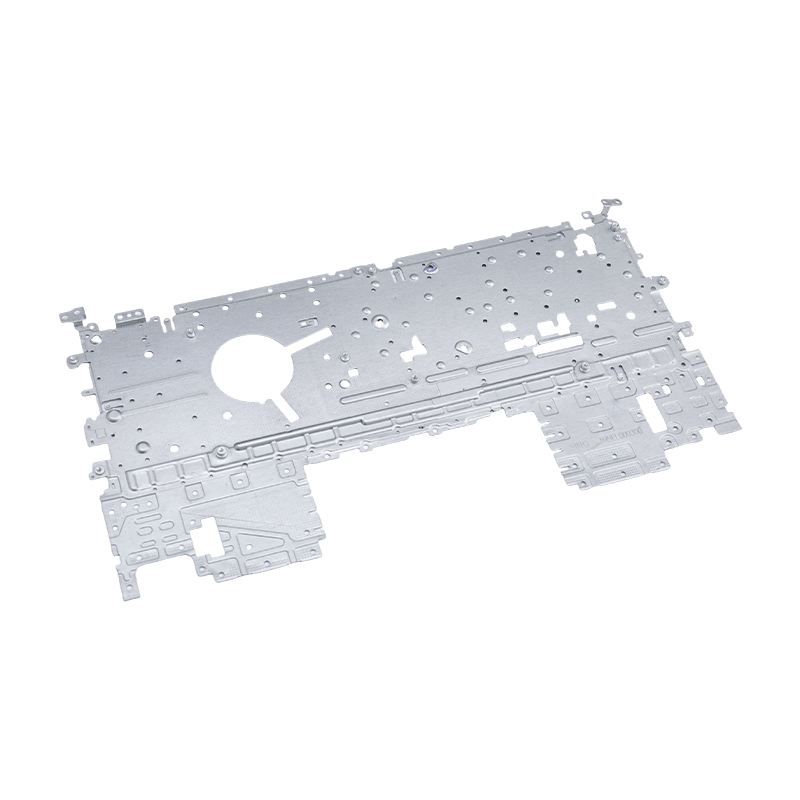

Laptop stamping parts

Our laptop stamping parts are precision-manufactur...

-

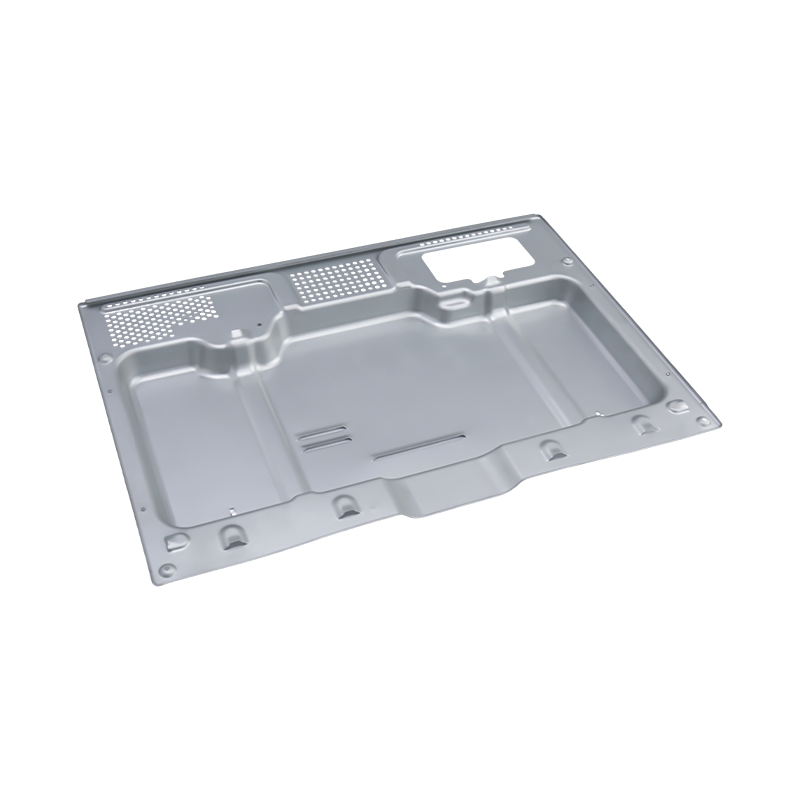

High-end oven stamping parts

Our High-end oven stamping parts are precision-man...

-

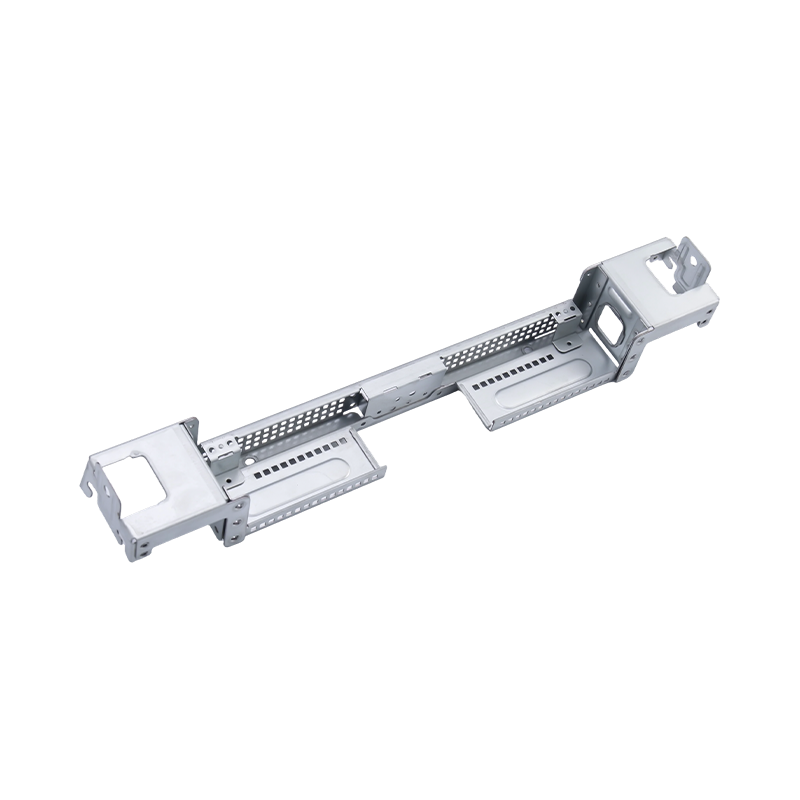

High-end large computer stamping parts

Our High-end large computer stamping parts are pre...

-

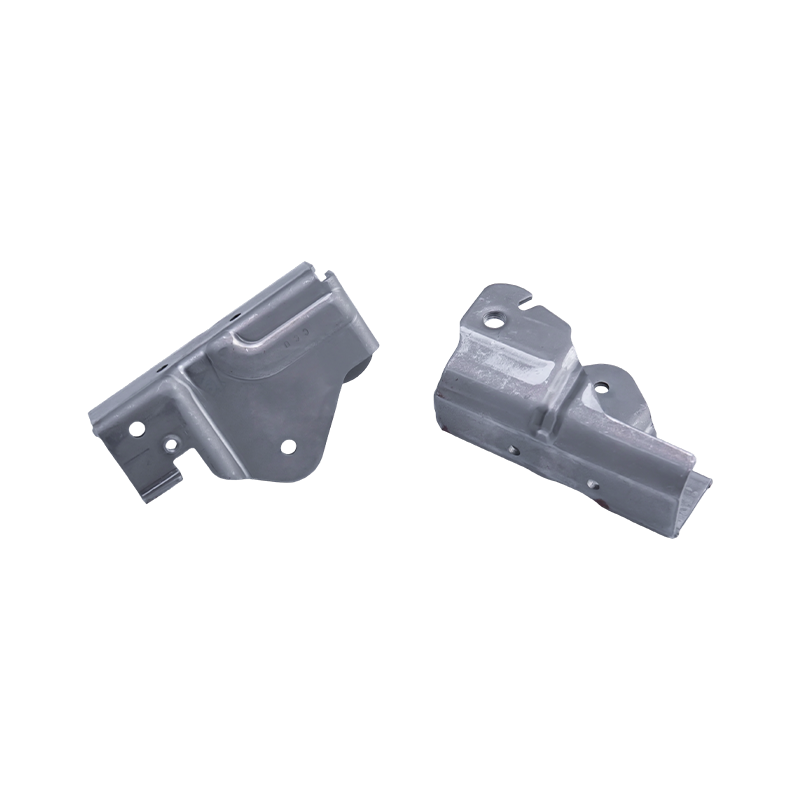

Car seat stamping parts

Car seat stamping parts are core metal components ...

The automotive stamping die industry is ushering in a new round of technological upgrades.

With the rapid development of new energy vehicles and intelligent manufacturing, the automotive stamping die industry is entering a new phase of technological upgrading and structural adjustment. As a crucial foundation for automotive parts manufacturing, stamping dies face higher demands in terms of precision, efficiency, and stability.

In recent years, the trend towards lightweighting in automobiles has become increasingly apparent, with the application of new materials such as high-strength steel and aluminum alloys in vehicle body structures expanding. This presents greater challenges to the structural design, material selection, and manufacturing processes of stamping dies. Dies not only need higher wear resistance and service life but also must maintain stable forming quality under complex forming conditions.

Simultaneously, the automotive industry's increasing demands for production efficiency and consistency are driving the development of stamping dies towards higher precision, standardization, and automation. By introducing precision machining equipment, digital design, and automated stamping production lines, die manufacturers are transforming from delivering single dies to providing systematic solutions.

In the new energy vehicle sector, the demand for key components such as battery housings, motor housings, and structural parts continues to grow, bringing new application scenarios to the stamping die industry. Related dies are increasingly emphasizing manufacturability analysis and mass production stability during the design phase to adapt to the rapid pace of product development.

Industry insiders say that the automotive stamping die industry will place greater emphasis on technological accumulation and comprehensive service capabilities in the future. Companies with capabilities in die manufacturing, stamping processes, and automation integration will have a more advantageous position in market competition, driving the industry towards high-quality and sustainable development.

English

English Español

Español Deutsch

Deutsch