Design Customized Research Manufacture

With over 15 years of experience in the mold industry, we provide integrated solutions from mold design

and customized development to precision manufacturing and automation support.

EXPLORE MORE

-

Quality GuaranteeVIEW MORE

Quality GuaranteeVIEW MOREA rigorous quality control system and precise testing procedures ensure that products are stable, reliable, and consistently meet high standards.

-

High-end ManufacturingVIEW MORE

High-end ManufacturingVIEW MOREBy introducing precision wire EDM machines from Japan, the company can achieve a processing accuracy within 0.002mm. Coupled with experienced assembly technicians and proper installation and debugging, the company can meet the technical requirements of customers' high-precision products.

-

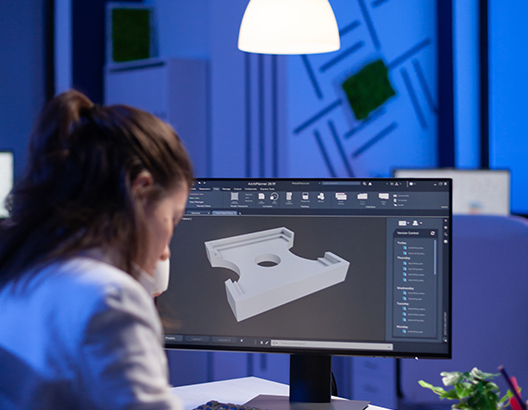

Research & DesignVIEW MORE

Research & DesignVIEW MOREStrong research and design capabilities enable customized solutions and continuous product optimization.

-

High-end CNC machine toolsVIEW MORE

High-end CNC machine toolsVIEW MOREThe company has multiple CNC machining equipment, which can process molds of various shapes and can also customize important components of complex molds according to customer needs.

Customized Solutions for All Industries

After years of precipitation, the company has mastered profound expertise and has been providing services to

high-quality original equipment manufacturers and well-known first-tier suppliers.

-

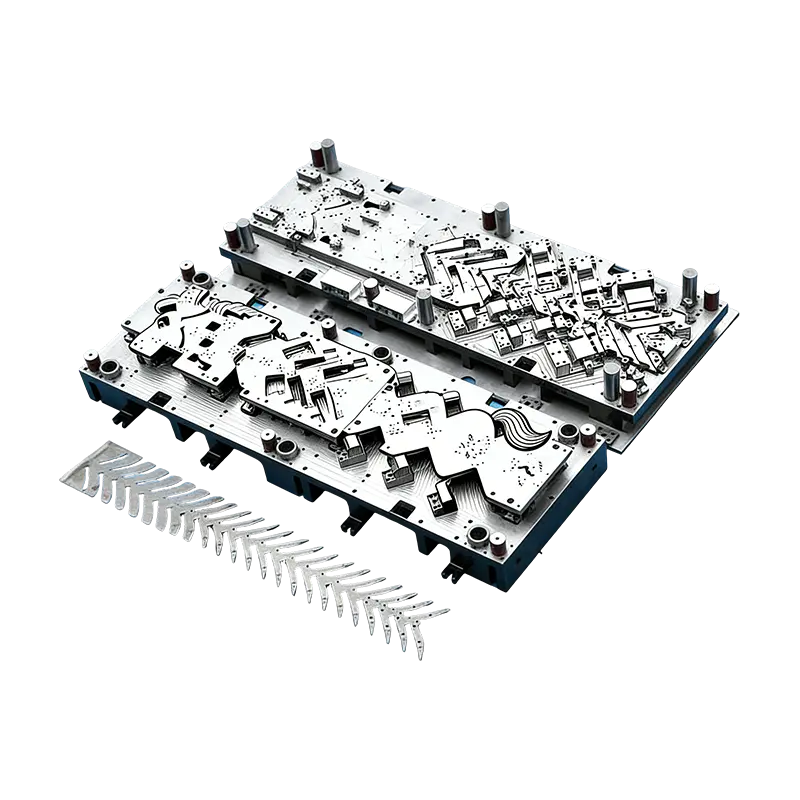

Molds

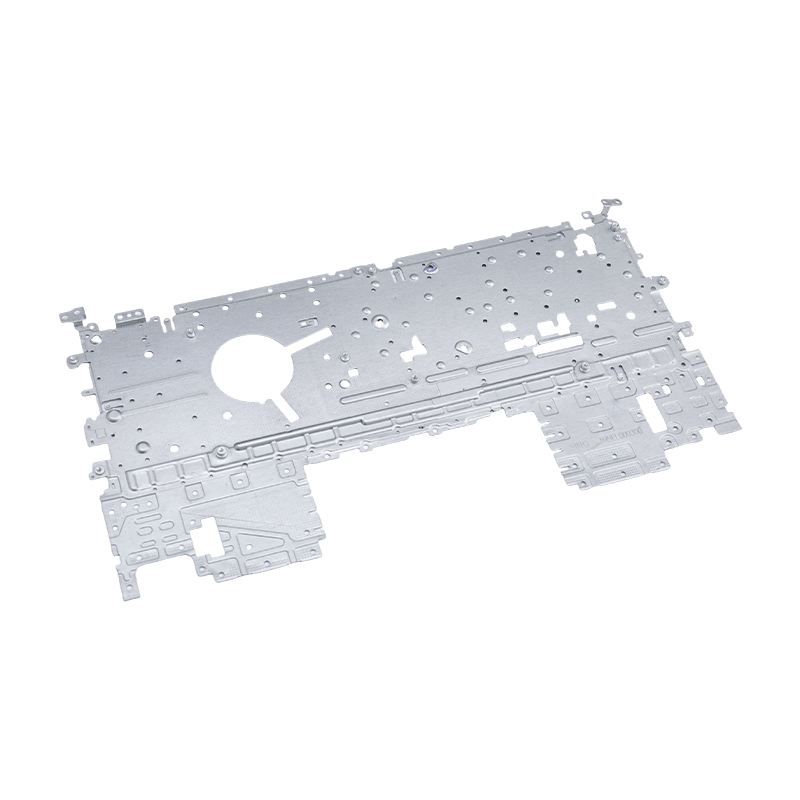

Molds Precision Molds

Precision Molds

-

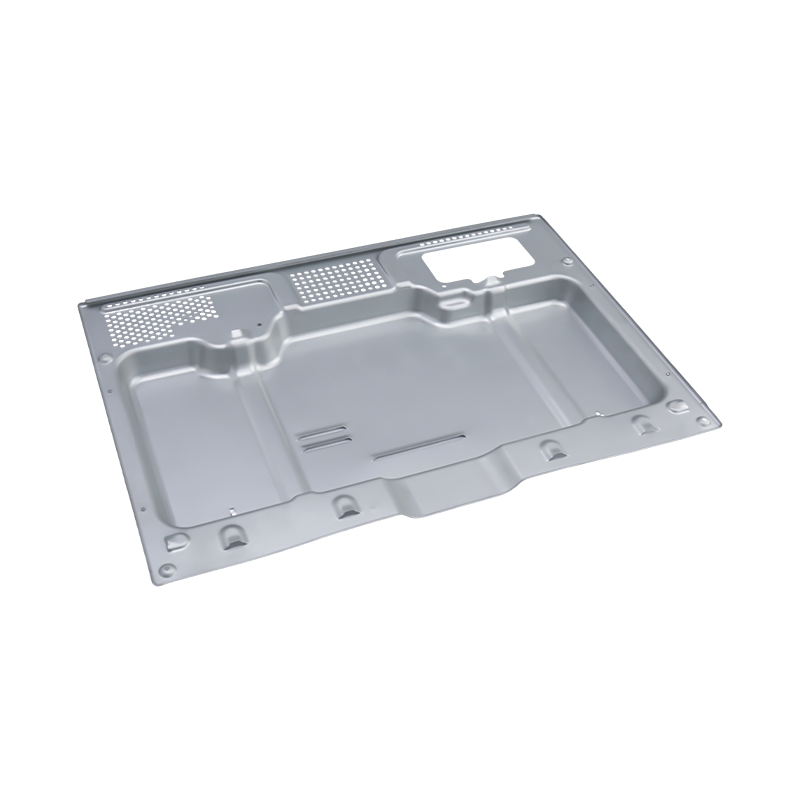

Products

Products Stamped parts

Stamped parts

-

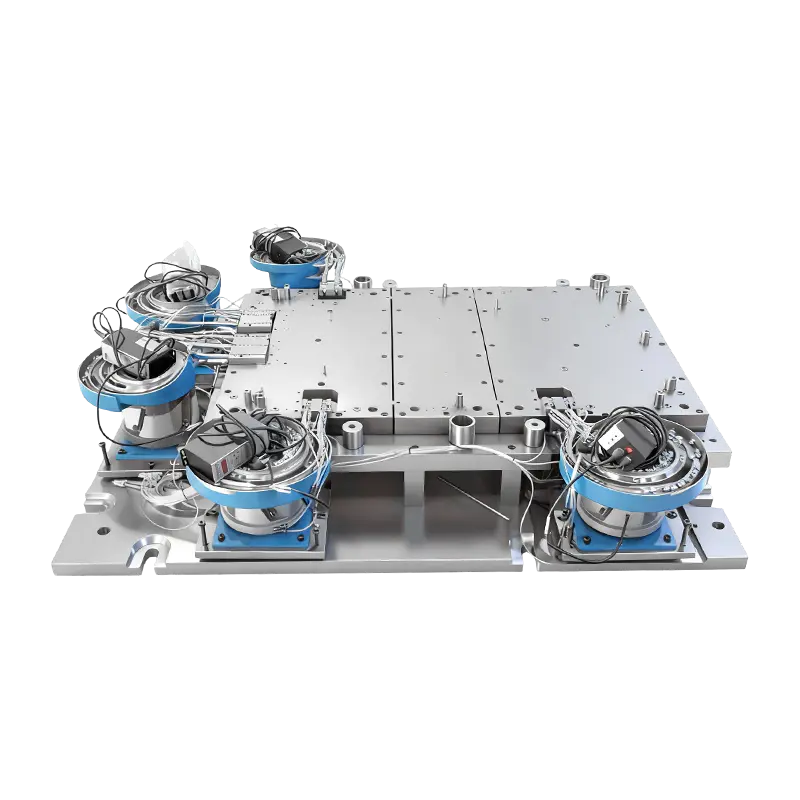

Automated Equipment

Automated Equipment Automation Equipment

Automation Equipment

Featured Products

Our products are designed with high precision, high stability, and high cost-effectiveness as core features

to meet the diverse needs of different customers.

ABOUT SHUANGQISI

Located at No. 118 Yexin Road, Wujiang District, Suzhou City, the company currently has 60 technical staff.

Through the joint efforts and continuous development of all employees, the company has become a professional

manufacturer of stamping dies and hardware parts with high cost performance, integrating design,

manufacturing, and service.

READ MORE

-

0Company Establish- ment Time

-

0+Professional and technical personnel

-

0+Professional mold equipment

International Qualifications

All of our products' quality has been approved by multiple worldwide renowned certificate bodies.

-

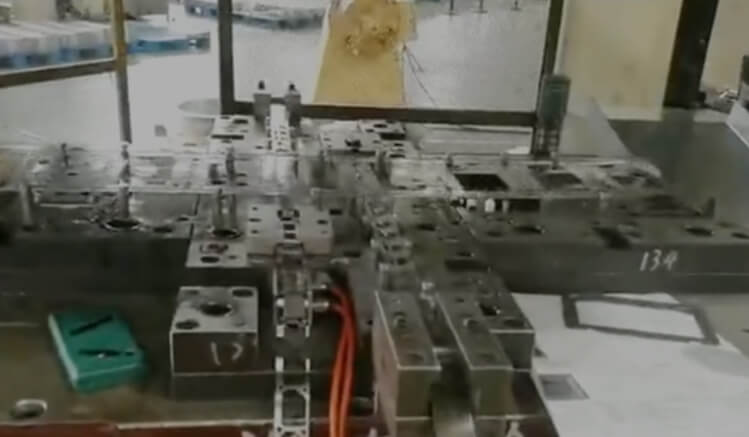

Mold Display

-

Automated Equipment

Manufacturing Capability

With advanced CNC machining centers, precision grinding equipment, and a full range of stamping presses

from 80T to 400T, we are fully equipped to handle both mold manufacturing and mass production of metal

stamping parts. Supported by skilled operators and experienced commissioning engineers, our manufacturing

system ensures high precision, stable quality, and efficient delivery for customers across various

industries.

Workshop Environment

A standardized workshop environment ensures precision manufacturing and consistent quality.

Benefits of Choosing Shuangqisi

We leverage our technological advantages to provide our customers with cost-effective stamped parts.

Outstanding Product Performance

SQS already built a multi-disciplinary team with years of expertise , experience , and also with the

ability to design ,research and develop synchronously with OEM customers .

-

Advance EquipmentAdvanced equipment ensures precision, stability, and consistent quality.

Advance EquipmentAdvanced equipment ensures precision, stability, and consistent quality. -

Multi-disciplinary teamA multi-disciplinary team ensures professional collaboration and reliable results.

Multi-disciplinary teamA multi-disciplinary team ensures professional collaboration and reliable results. -

Quality GuaranteeStrict quality control ensures reliable and consistent quality.

Quality GuaranteeStrict quality control ensures reliable and consistent quality. -

High technology & ExperienceHigh technology and experience ensure precision, reliability, and quality.

High technology & ExperienceHigh technology and experience ensure precision, reliability, and quality.

Checkout Our Current News

Focusing on technology innovation and industry applications.

English

English