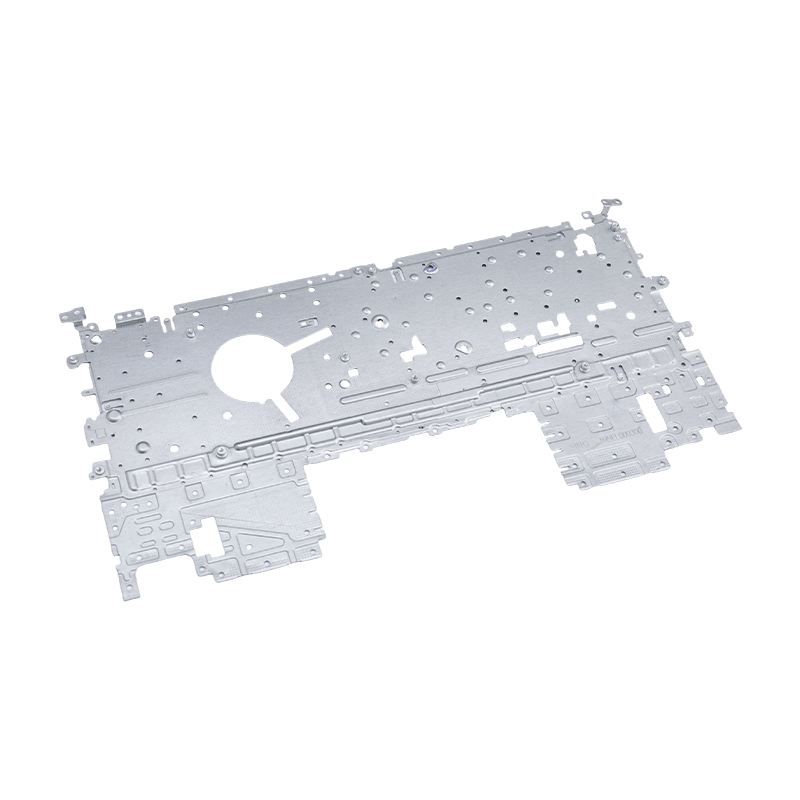

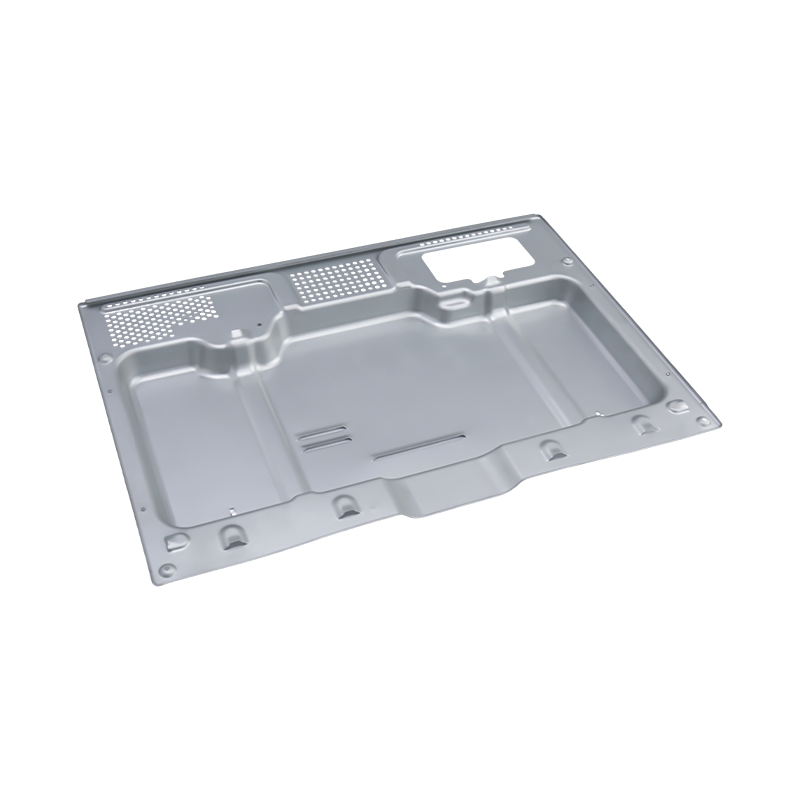

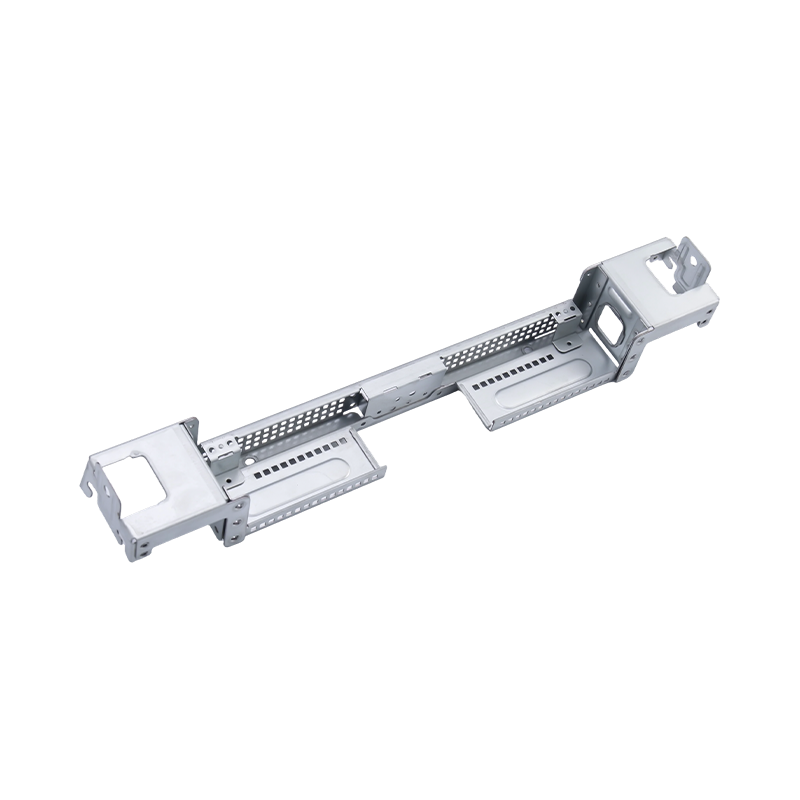

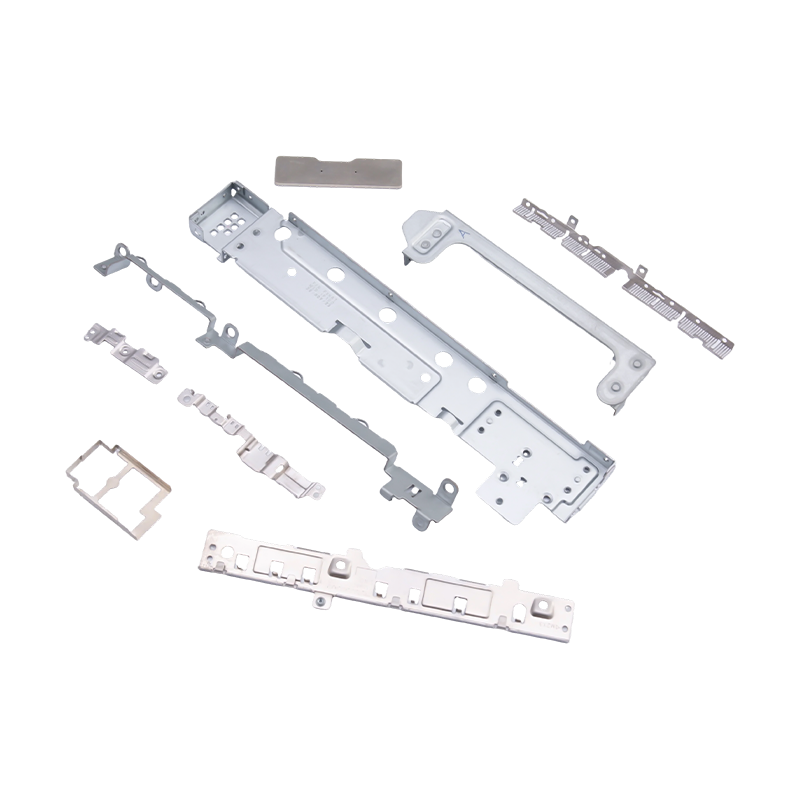

Suzhou Shuangqisi Mold Equipment Co., Ltd., located at No. 118 Yexin Road, Wujiang District, Suzhou City, has 60 technical staff. Through the joint efforts and continuous development of all employees, the company has become a professional manufacturer of stamping dies and hardware parts, offering high-quality products at competitive prices, integrating design, manufacturing, and service.

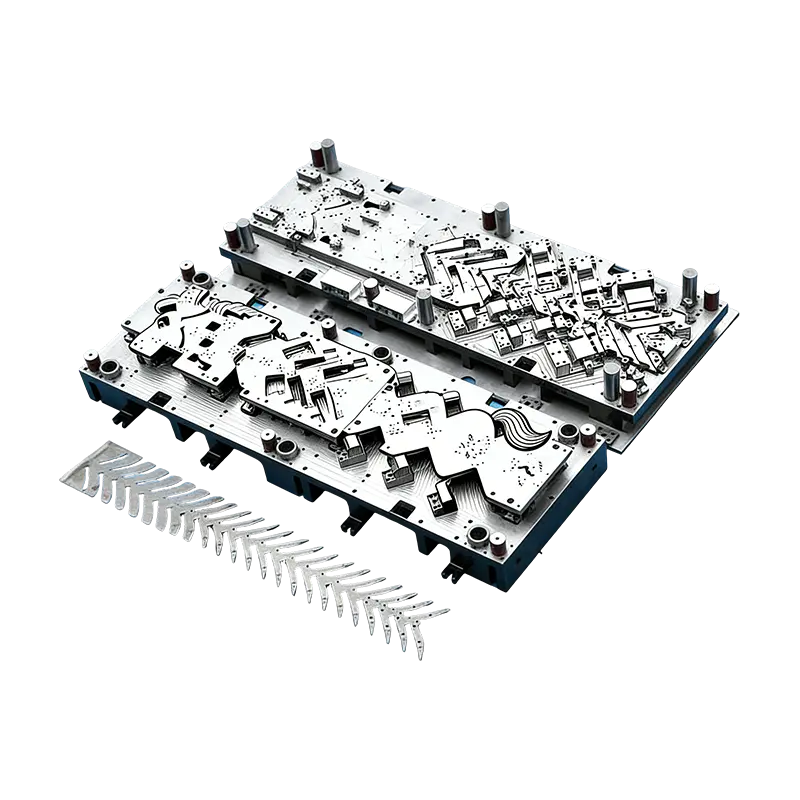

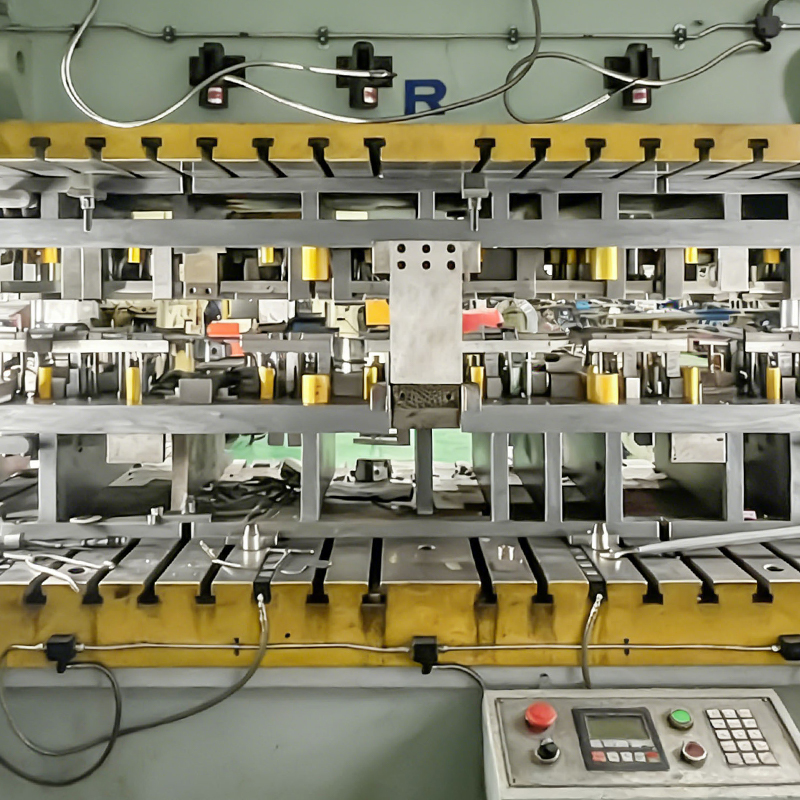

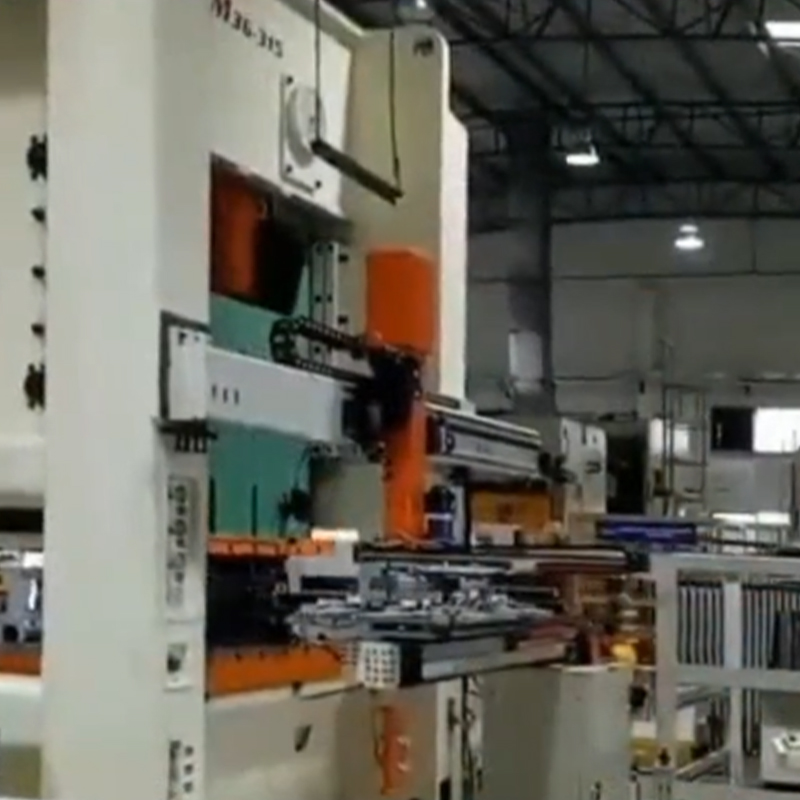

The company possesses imported wire cutting machines, CNC machining centers, over 10 grinding machines of various sizes, and 25 punch presses (80T-400T), among other advanced precision machine tools. It has also trained many senior operators and experienced debugging personnel, enabling it to meet the needs of diverse customers.

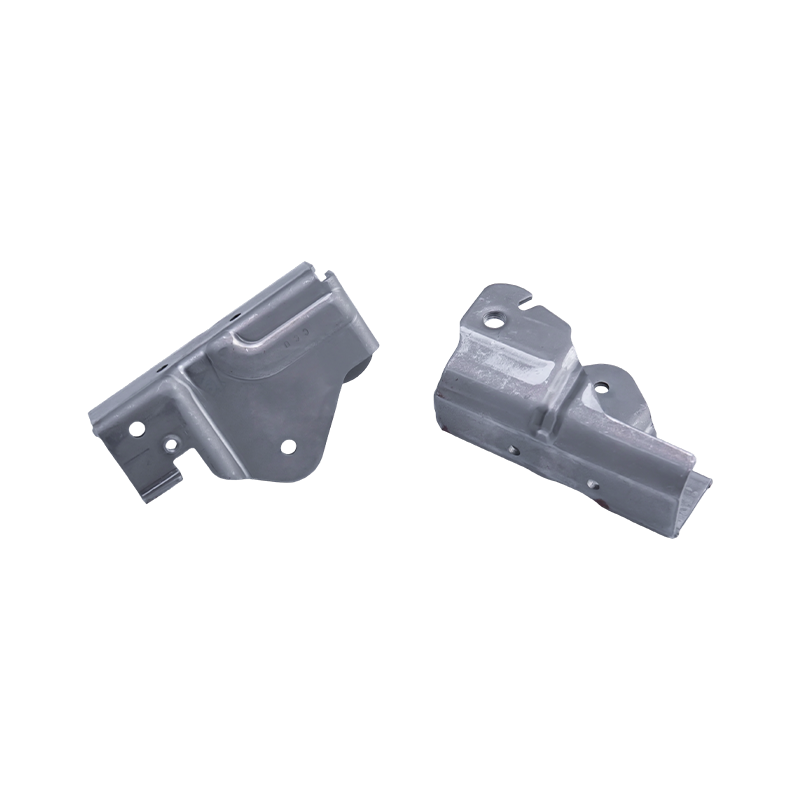

Currently, the company's main clients include Anter Group, Ousheng Electric, Dongbei Group, and Huichuan Technology, primarily supplying molds and products for servo drives, compressors, and new energy vehicles. The company's technical level is among the leading in the industry, with an experienced team that is dedicated to technological advancement. The company focuses on creating value for its customers and adheres to high-quality development.

With 15 years of experience in the mold industry, the company has accumulated a large number of technical talents. As early as 2016, it invested in and established Suzhou Keshuang Intelligent Technology Co., Ltd., which mainly produces stamping automation equipment. With many years of experience, it can provide customers with turnkey projects for stamping molds and stamping automation. The company can also invest in related production equipment according to customer needs to create cost-effective products and services for customers.

English

English Español

Español Deutsch

Deutsch