Industry Knowledge

Material Flow Optimization in Deep Drawn Metal Stamping for Complex Geometries

In Deep Drawn Metal Stamping, controlling material flow is essential when producing cylindrical or box-shaped components with high depth-to-diameter ratios. Engineers often focus on blank holder force balance, lubrication selection, and draw bead positioning to avoid wrinkling or tearing. Advanced simulation tools allow manufacturers to predict strain distribution before tool fabrication, significantly reducing trial costs and improving consistency in Metal Stamping Product quality.

From our practical experience in tooling design and debugging, we have found that combining precise CNC machining with experienced die spotting personnel greatly improves forming stability. With multiple punch presses ranging from 80T to 400T and precision machining equipment, we are able to fine-tune die clearance and radius transitions to match specific material grades required by customers in servo drive and new energy vehicle industries.

- Optimize punch and die radius based on material elongation properties

- Use progressive forming stages instead of single deep draw for extreme depths

- Apply high-performance lubricants to reduce friction and galling

- Monitor thinning distribution using forming simulation software

Tool Life Improvement Strategies for High-Volume Metal Stamping Product Manufacturing

For high-volume Metal Stamping Product production, tool life directly influences cost efficiency and delivery reliability. Wear typically occurs at cutting edges, forming radii, and guide components. Surface treatments such as TiN, TiCN, or DLC coatings can significantly extend tool lifespan, especially when processing stainless steel or high-strength alloys commonly used in compressors and automotive components.

With more than 15 years of mold industry experience, we continuously invest in grinding machines and wire cutting equipment to maintain dimensional precision. Our engineering team often recommends modular die structures, allowing quick replacement of wear components instead of complete tool refurbishment, which minimizes downtime for customers.

| Wear Factor | Primary Cause | Improvement Method |

| Edge Chipping | High impact load | Coatings and radius optimization |

| Adhesive Wear | Poor lubrication | Lubricant selection and polishing |

| Abrasion | Hard material particles | Surface hardening treatments |

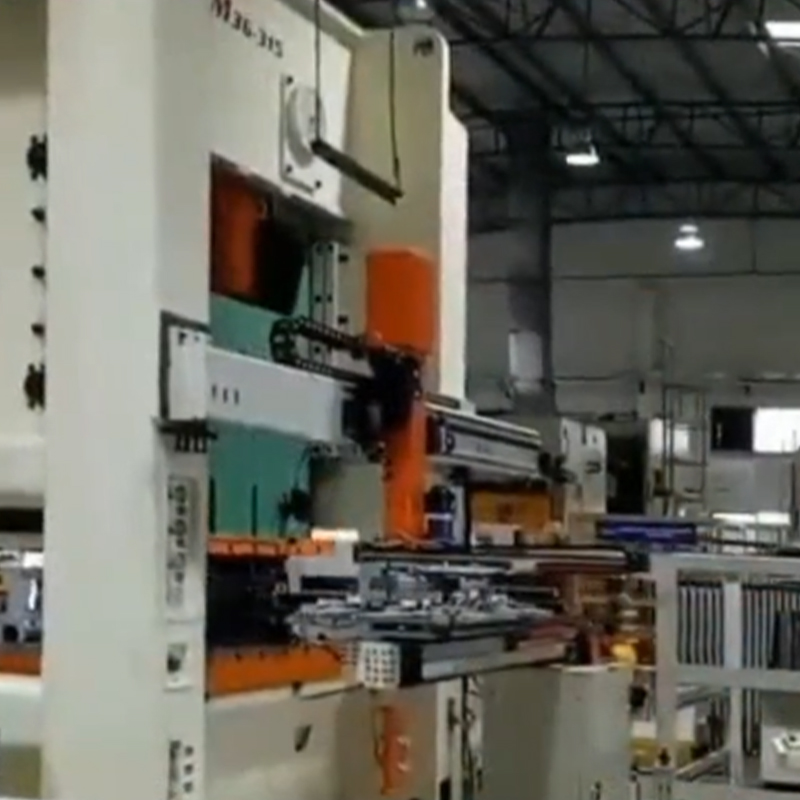

Automation Integration Trends in Deep Drawn Metal Stamping Production Lines

Automation is rapidly transforming Deep Drawn Metal Stamping processes, particularly in industries requiring consistent precision such as new energy vehicles and industrial electronics. Robotic loading systems, transfer mechanisms, and inline inspection devices reduce labor dependency and improve throughput stability. Automated stamping lines also enable real-time production monitoring, ensuring traceability and defect reduction.

As a manufacturer that invested early in stamping automation equipment through our affiliated intelligent technology company, we are able to provide turnkey solutions combining molds, automation systems, and production equipment. This integrated approach allows customers to shorten project launch cycles while maintaining competitive costs.

- Robotic arm transfer systems for multi-stage forming

- Vision inspection for dimensional and surface defects

- Automated lubrication and cleaning modules

- Data integration with MES or ERP systems

Design Considerations for Lightweight Metal Stamping Product in New Energy Applications

Lightweight design has become a key requirement in Metal Stamping Product development for electric vehicles and energy-efficient equipment. Engineers increasingly select aluminum alloys, high-strength steel, or hybrid materials to reduce weight without sacrificing structural integrity. However, these materials introduce new challenges such as springback control and tool wear acceleration.

Our collaboration with clients in servo drive and compressor sectors has shown that early co-development between product designers and die manufacturers significantly improves manufacturability. By adjusting forming sequences, adding stiffening ribs, or modifying flange geometry, it is possible to achieve both weight reduction and production efficiency.

Companies with strong technical teams and advanced machining capabilities are better positioned to support such projects. With dozens of skilled technicians and experienced debugging personnel, we focus on delivering cost-effective solutions while maintaining high-quality standards, helping customers create long-term value in competitive markets.

English

English Español

Español Deutsch

Deutsch